After years of accumulation, the Shanghai Research Institute of Sinopec Lubrican...

details

Product Introduction

This product is a solution of polymethacrylate in deeply refined mineral oil, viscosity index improver with high shear stability. In the blending process of low temperature hydraulic oil and other oil products, it has a smaller amount of addition, excellent low temperature performance, SCR-9100 can effectively improve the viscosity index of oil, save the amount of pour point depressor, reasonable price, has a huge economy, and can effectively save production costs for customers.

Product Performance

Narrow molecular weight distribution, strong thickening ability, good low temperature fluidity, anticoagulant effect and excellent shear stability, excellent coagulation effect especially for hydrotreating base oil.

Product Usage

Suitable for blending low temperature hydraulic oil and internal combustion engine oil and other oils, can effectively improve the viscosity index of oil, under the premise of ensuring shear stability, it has the double effect of improving the viscosity index and reducing the pour point, and effectively save the product formula cost.

Physical and chemical index evaluation

The evaluation is carried out according to SH/T0622-2007 standard

The kinematic viscosity, flash point and thickening ability of the viscosity index improver are measured.

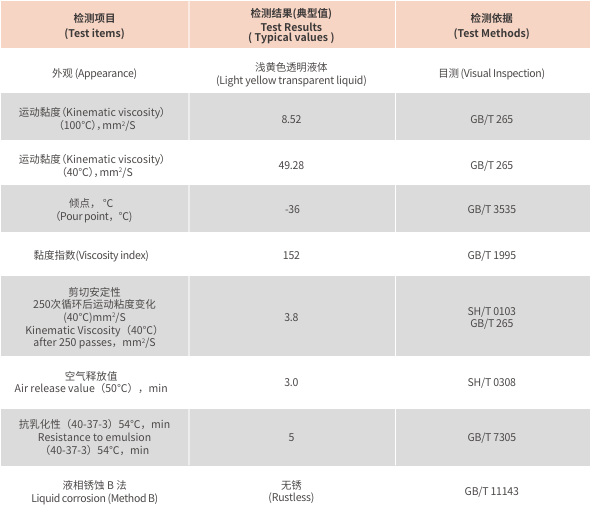

The main physical and chemical indexes of SCR-9100 viscosity index improver are shown in Table 1

Performance testing - Applications

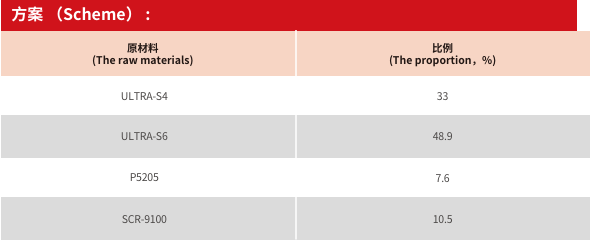

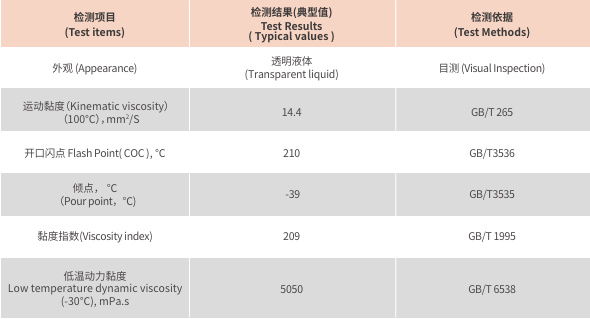

SCR-9100 blended HV 46 performance data:

Performance data:

SCR-9100 blended SM 5W-40 performance data:

Performance data:

Conclusion

Suitable for blending low temperature hydraulic oil and internal combustion engine oil and other oils, can effectively improve the viscosity index of oil, under the premise of ensuring shear stability, it has the double effect of improving the viscosity index and reducing the pour point, and effectively save the product formula cost.

Packing and precautions

Please refer to SH/T0164 for transportation, storage and handling. Net weight: 170Kg/drum, packed in 200 liter metal drum. Non-flammable, non-explosive, non-corrosive.Best Blending temperature: 50-60℃.Storage temperature below 60℃, avoid repeated heating, keep away from heat.