After years of accumulation, the Shanghai Research Institute of Sinopec Lubrican...

details

一、Product Introduction

The utility model relates to a new type viscosity index improver for Ethyl-propylene copolymer, which is made of deeply refined hydrotreating base oil, through thermal melting and catalytic degradation at high temperature, and then through homogenizing machine high pressure degradation, and through filtration treatments.

二、Product Performance

Good thickening ability, excellent low temperature cold start performance and excellent shear stability and excellent high temperature and high shear performance.

三、Product Usage

Suitable for the preparation of high-grade internal combustion engine oil, automatic transmission fluid, gear oil and industrial lubricating oil and other kinds of oil, effectively reduce the cost of oil blending, is a powerful substitute for traditional adhesive finger.

In diesel engine oil blending, compared with other adhesive products, it has better low temperature performance, high temperature and high shear performance and excellent shear stability, which can effectively maintain oil pressure and provide lasting viscosity protection.

四、Evaluation of viscosity index improver

The evaluation is carried out according to SH/T0622-2007 standard.

Plan 1

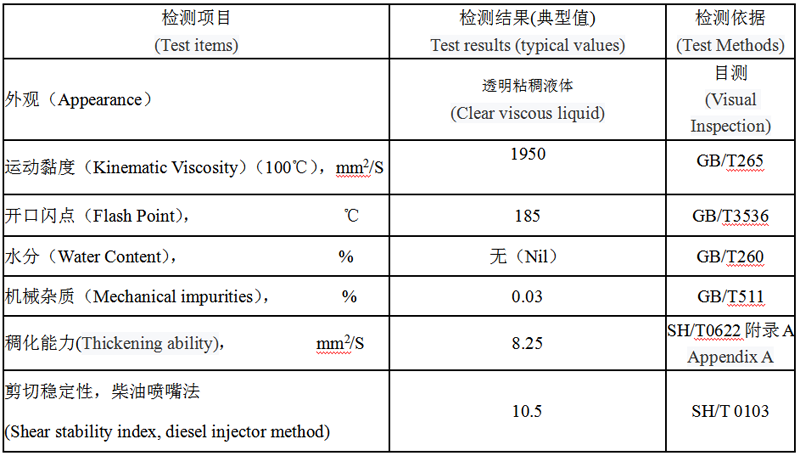

10% (mass fraction) SCR-616 was added to Dalian HVI150 base oil, heated to 60℃~70℃, and stirred evenly to obtain the sample. The shear stability index (diesel nozzle method) and thickening ability of the sample are determined.

The main physical and chemical indexes of SCR-616 viscosity index improver are shown in Table 1

Table 1 Main physical and chemical indexes of SCR-616 viscosity index improver

Plan 2

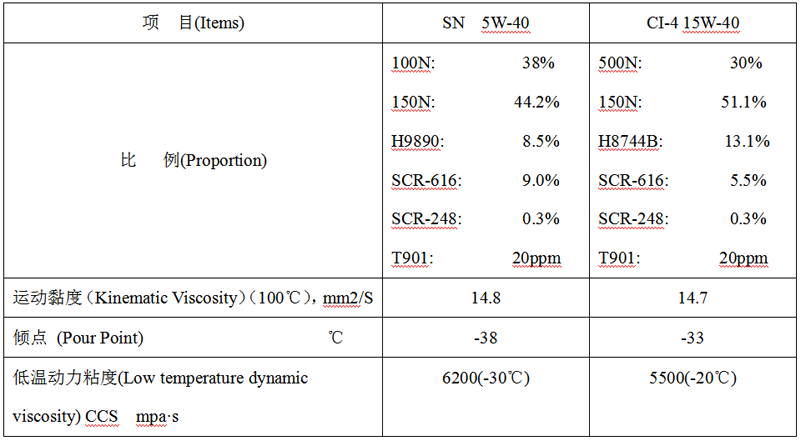

SN 5W-40 and CI-4 15W-40 are modulated by gasoline and diesel oil compound, hydrogenation base oil and viscosity index improver SCR-616. Kinematic viscosity, pour point and dynamic viscosity at low temperature are measured. The blending scheme and experimental analysis results are shown in Table 2.

Table 2 Blending scheme and experimental analysis results

Packing and precautions

Please refer to SH/T0164 for transportation, storage and handling. Net weight: 170 Kg/drum, packed in 200 liter metal drum. Non-flammable, non-explosive, non-corrosive.Best Blending temperature: 50-60℃.

Storage temperature below 60℃, avoid repeated heating, keep away from heat.