After years of accumulation, the Shanghai Research Institute of Sinopec Lubrican...

details

一、Product Introduction

This product is a solution of polymethacrylate in a highly refined mineral oil. It is a viscosity index improver specially designed for long span vehicle gear oil with high shear stability.

二、Product Performance

With narrow molecular weight distribution and excellent shear stability, it can meet the requirements of the new national standard. Excellent low temperature performance, can effectively inhibit wax crystallization, for different viscosity of the base oil has an excellent pour point effect.

三、Product Usage

It is suitable for the modulation of long-span vehicle gear oil, and can effectively improve the viscosity index of the oil. Under the premise of ensuring the shear stability, it has the double effects of improving the viscosity index and reducing the pour point, and effectively saves the formula cost of the product.

四、Evaluation of viscosity index improver

The evaluation is carried out according to SH/T0622-2007 standard.

The kinematic viscosity, flash point and thickening ability of the viscosity index improver are determined.

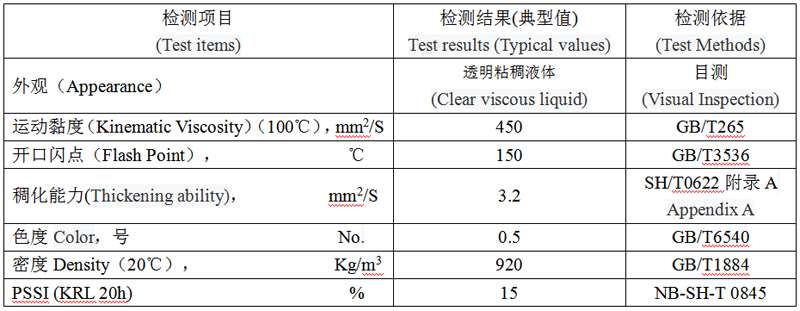

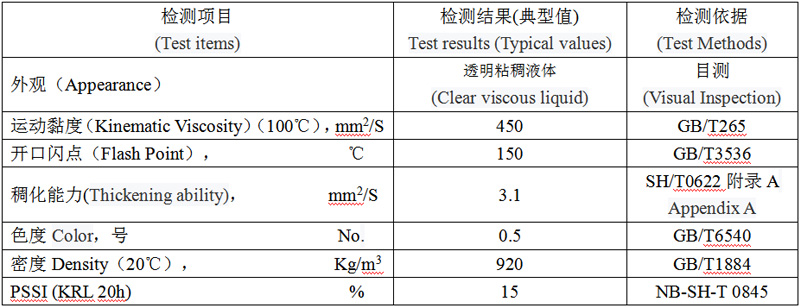

Main physical and chemical indexes of SCR-9050 viscosity index improver are shown in Table 1

Table 1 Main physical and chemical indexes of SCR-9050 viscosity index improver

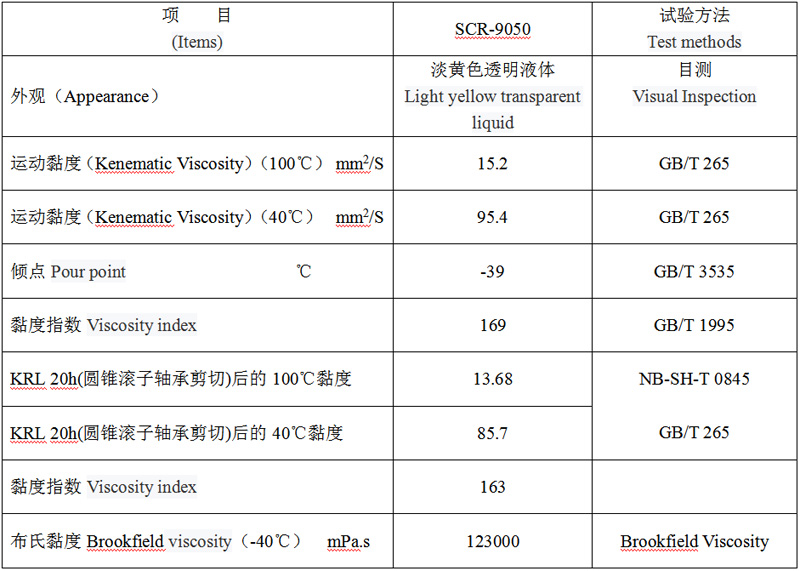

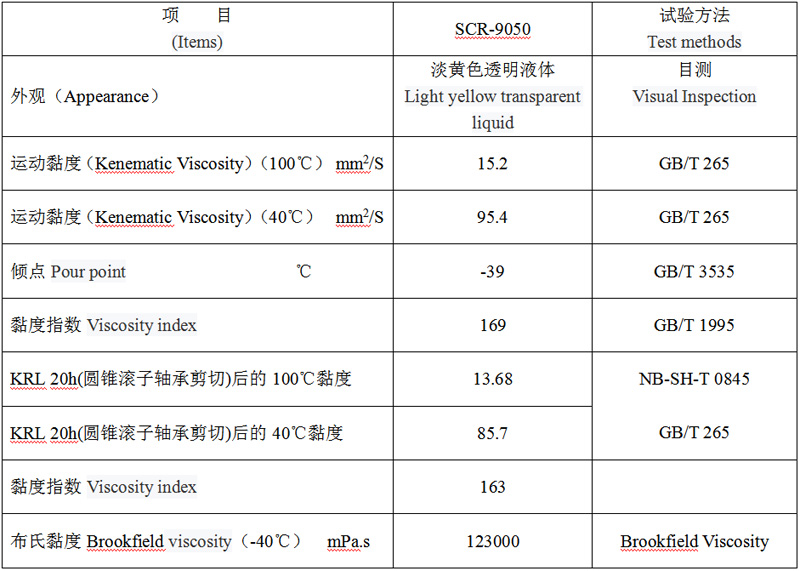

Performance testing - Applications

SCR-9050 blended GL-5 75W-90 gear oil performance data:

Plan :

The performance data

五、Recommended dosage:The recommended dosage of SCR-9050 is 3-25% for use in long-span viscosity grade vehicle gear oils or other oils with special requirements for shear stability. The specific amount depends on the actual application. For details, please consult our additive application engineers.

六、Packing and precautions

Please refer to SH/T0164 for transportation, storage and handling. Net weight: 170 Kg/drum, packed in 200 liter metal drum. Non-flammable, non-explosive, non-corrosive.Best Blending temperature: 50-60℃.

Storage temperature below 60℃, avoid repeated heating, keep away from heat.